String of beads, 3650-3100 BC.

The history of jewellery making dates back millennia, with the first know jewellery pieces – specifically perforated beads made from seashells, being created by Neanderthals around 115,000 years ago. Stone, marble and ostrich egg pieces, dating to around 40,000 years ago have been found in Kenya and Russia, with crude necklaces and bracelets made from bone, berries, teeth and stone dating to around 11,000BC being found in Europe.

Copper jewellery began appearing 7,000 years ago, with the first established jewellery making practices in Ancient Egypt around 3,000–5,000 years ago. The Egyptians preferred the luxury of gold and other metals over copper, and their jewellery would often symbolise political and religious power, being worn by wealthy Egyptians in both life and death.

Around 5,000 years ago jewellery-making had become a significant craft in Europe and the Middle East with the ancient civilisations of Mesopotamia, Greece, Rome and the Etruscan’s manufacturing jewellery using precious metals and semi-precious stones.

It is thought that diamonds were originally mined in India 3,000-6,000 years ago, with the Romans importing Indian diamonds and Sri Lankan sapphires as early as 2,000 years ago, whilst in Roman-ruled England Whitby Jet was being carved into jewellery pieces. Both Greek and Roman jewellery was often worn to give the wearer protection from the ‘Evil Eye’ or endow them with supernatural powers.

The Indian subcontinent has the longest continuous legacy of jewellery making in the world with over 5,000 years of manufacturing. Chinese jewellery-making began at a similar time and became more widespread with the spread of Buddhism around 2,000 years ago.

By the 17th Century, the Renaissance and increased trade throughout the world had a significant impact on jewellery in Europe, with a wider variety of gemstones and exposure to different cultures seeing an increase in jewellery that showcased gemstones and their settings. A trend that has continued with modern jewellery.

Formlabs Form 3 Printer

With the advent of new materials, colouring techniques, computer aided design (CAD) and 3D printing, modern jewellery comes in a multitude of styles.

3D printing as a production technique has gained more importance over the last few years and for that reason Form Bespoke Jewellers recently invested in a 3D printer for our Leeds workshop. Although we won’t use 3D printing in the manufacturing process of the bespoke jewellery our customers take home, 3D printing allows us to create a 3D model for our customers to view, try-on and check over before the final precious metal piece is handmade by our jewellers.

After much research Form Bespoke Jewellery purchased the Formlabs - Form 3 Printer. This Low Force Stereolithography (LFS) technology 3D printer uses linear illumination (lasers) and a flexible tank to turn liquid resin into solid parts, delivering accurate and repeatable prints.

So whilst jewellery making may have millennia of history, and to this day we still use techniques that have been used for thousands of years, new technologies play a vital role in our industry for both our jewellers and our customers.

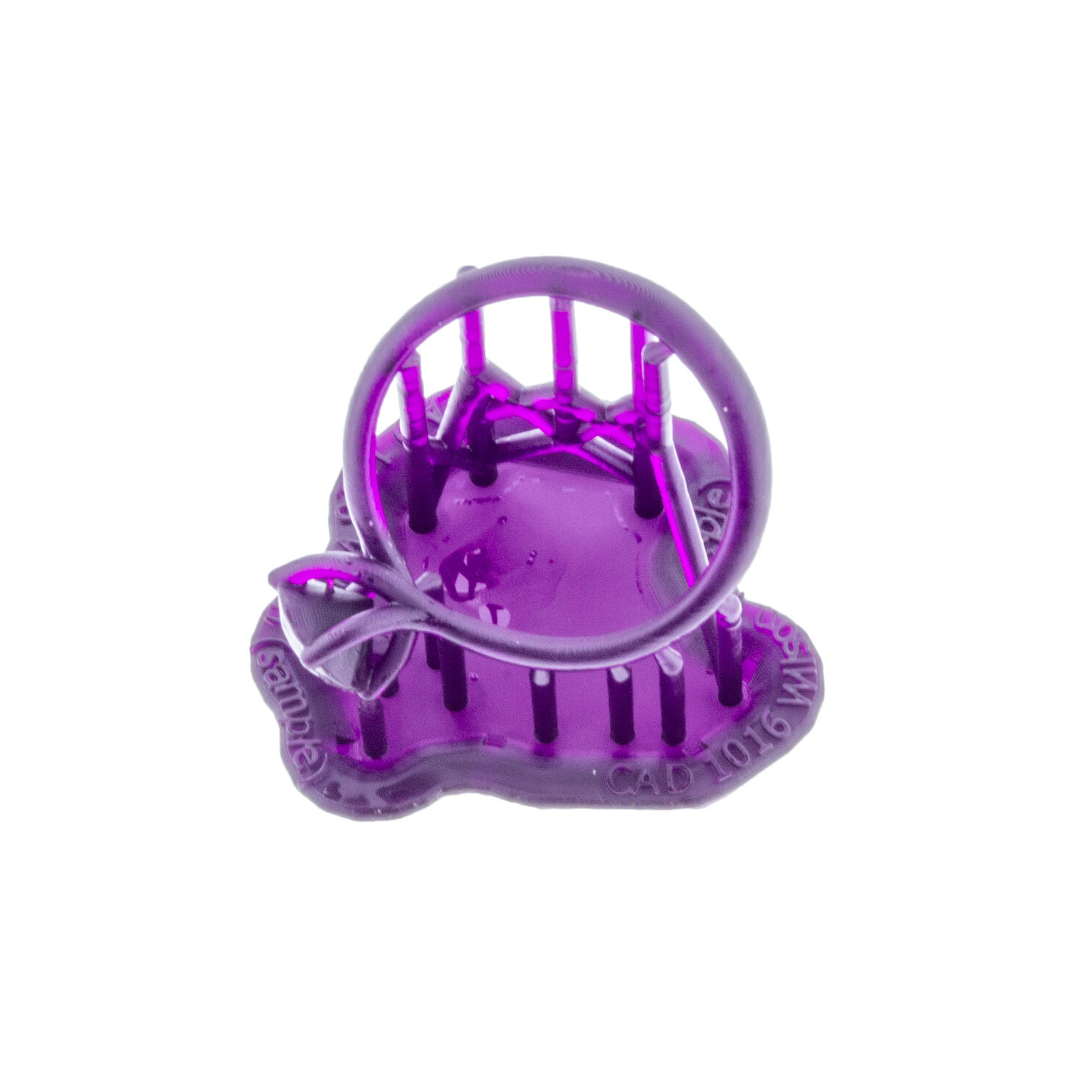

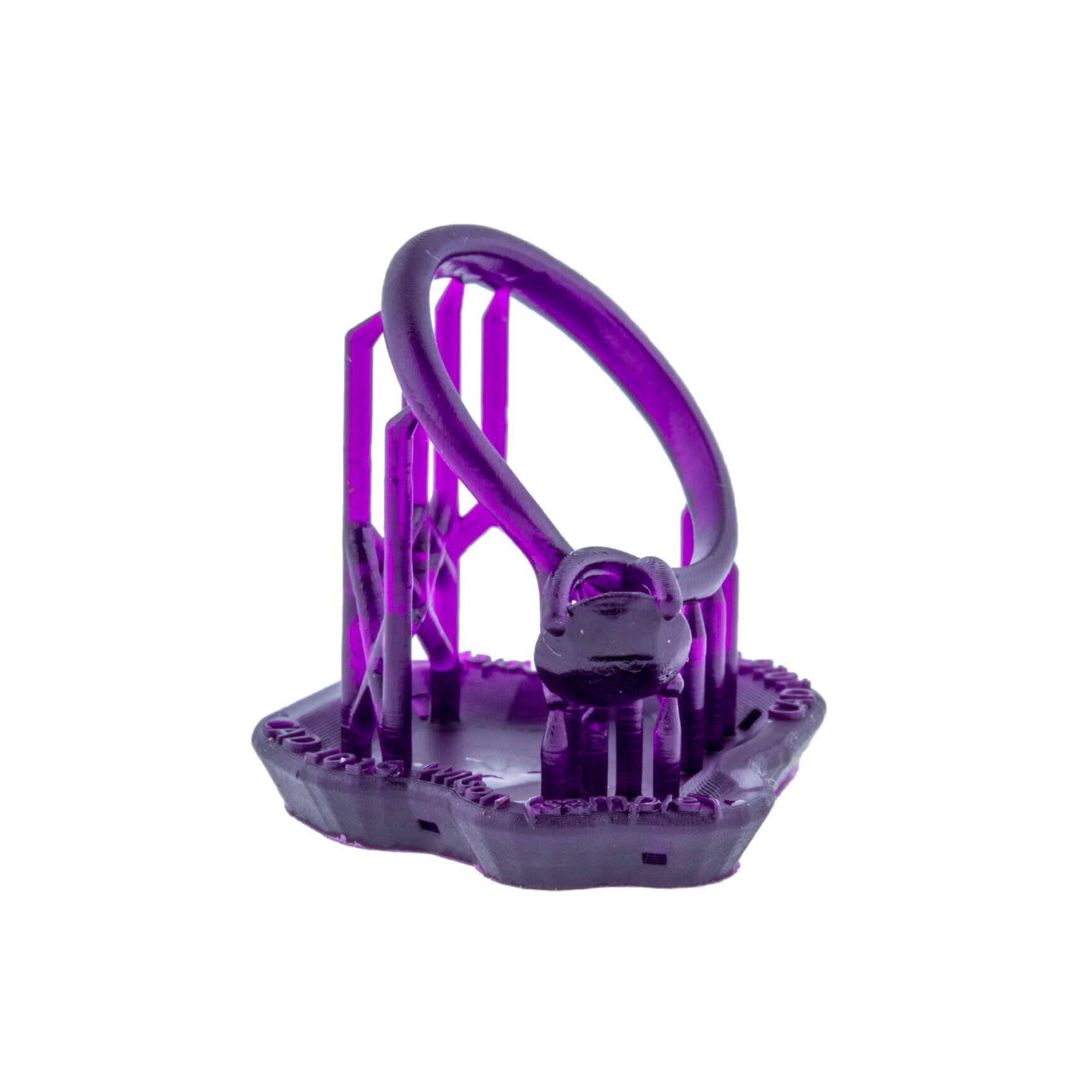

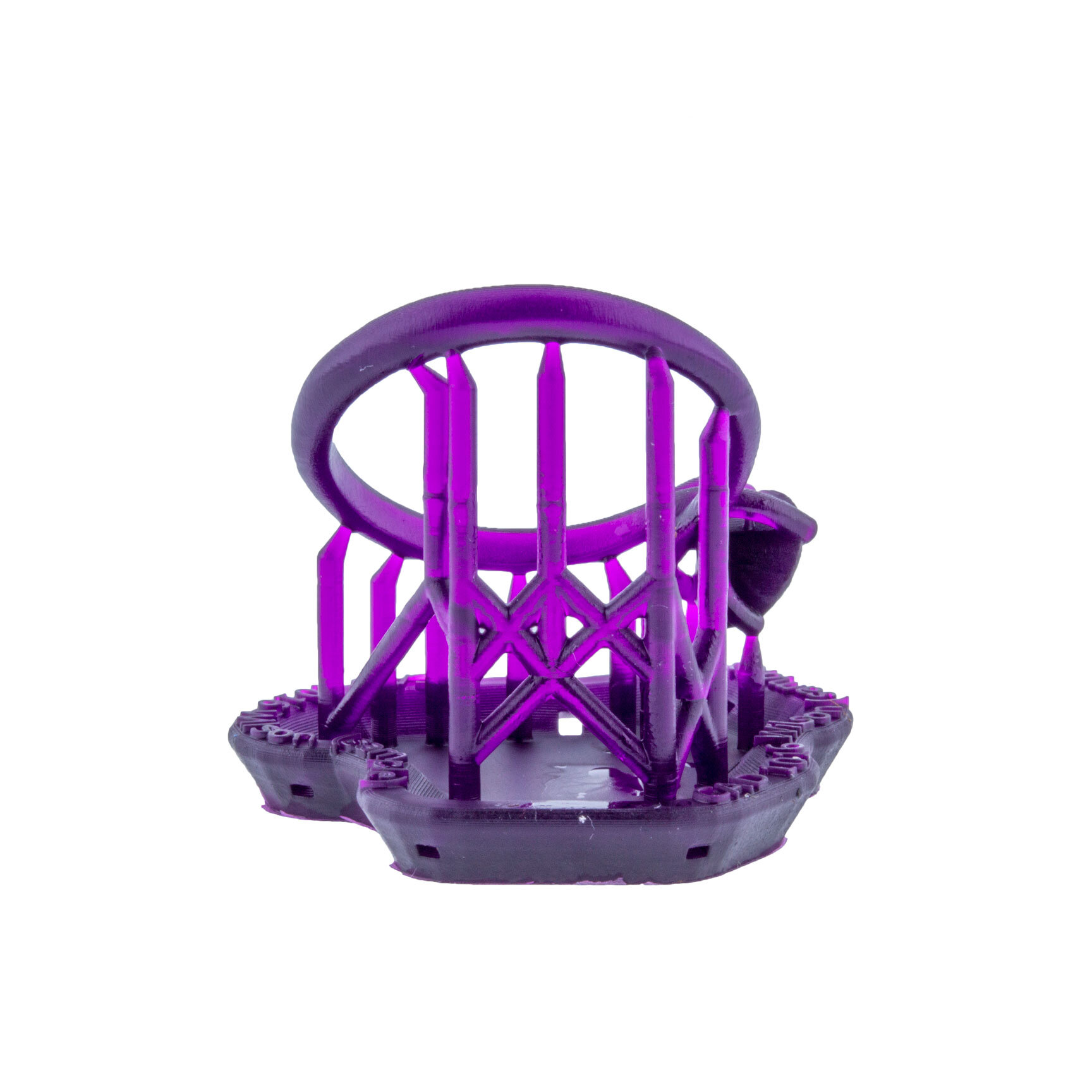

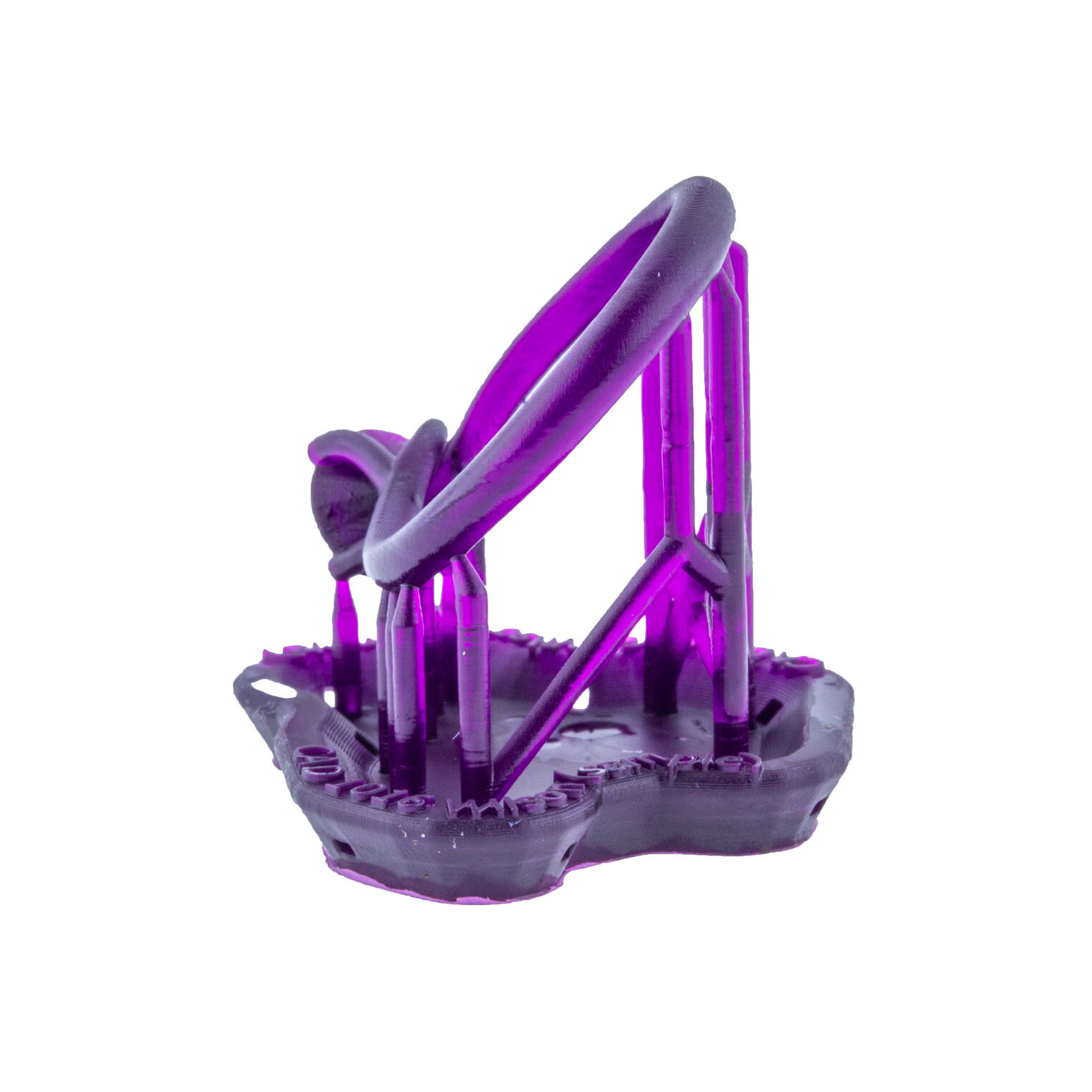

Below are photos of the first 3D printed ring we produced, once it has been detached from the light-touch supports (scaffolding like structure around the ring) it is ready for our customer to try-on.

If you would like more information about the bespoke jewellery our Leeds jewellers can create for you please contact us.